Geckos have the ability to stick readily to almost any surface. Writing in the Journal of Polymer Science: Polymer Physics, Boxin Zhao and colleagues show that the nonsticky fluropolymer, Teflon AF, applied to nanostructures with a “fluffy” top layer can create a similar adhesion strength for both wet and dry conditions.

Geckos have the ability to stick readily to almost any surface. Writing in the Journal of Polymer Science: Polymer Physics, Boxin Zhao and colleagues show that the nonsticky fluropolymer, Teflon AF, applied to nanostructures with a “fluffy” top layer can create a similar adhesion strength for both wet and dry conditions.

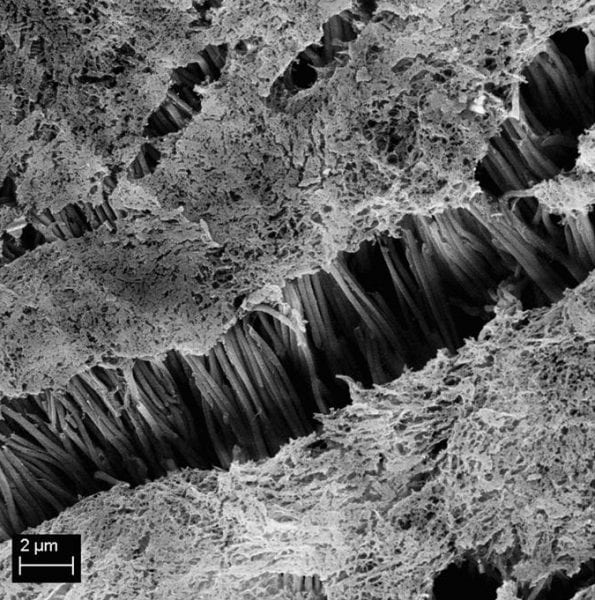

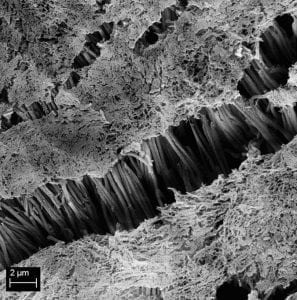

Geckos’ superior adhesive ability is attributed to the millions of finger-like spatulas of β-keratin making up their foot pads. “This work is inspired by the Gecko lizards’ amazing aptitude to stick to almost any surface (whether hydrophilic or hydrophobic, rough or smooth) and to well adapt to both dry and wet conditions.” says Zhao. “This type of hierarchical nanopillar has the potential application as an efficient dry adhesive which can generate strong adhesion both in air and under water.”

According to the authors, previous gecko-inspired dry adhesives have been fabricated from such polymers as polydimethylsiloxane (PDMS), polyurethane, and polypylene. However, self-adhesion between the nanoscale features causes the structures to bundle up or collapse.

The researchers studied the nonsticky fluropolymer, Teflon AF, a copolymer of perfluro-2,2 dimethyl dioxole and tetrafluroethylene. It has rigidity similar to β-keratin, and an extremely low surface energy and dielectric constant. The high electronegativity of the fluropolymers can ease the trapping of electrons at the surface, producing strong electrostatic interactions.

The adhesive performance of the Teflon AF nanopillars was shown through indentation tests. The results were given for the penetration depth and pull-off force for both wet and dry conditions. Though the nanopillars generated considerable adhesion for dry conditions, they performed remarkably under water at about 70% of the dry adhesion, which has rarely been seen in previously reported studies.

“One unique feature is the top terminating layer of a ‘fluffy’ nanostructure which effectively hindered the self-sticking of the high aspect-ratio, high density nanopillars and delivered superior conformability to substrate surfaces.” explains Zhao. These “fluffy” nanostructures can assist the separation of charges thereby enhancing electrostatic interactions as compared to a flat surface.

“Future studies will focus on determining the mechanism of the formation of the top terminating layer and quantifying different sources of adhesion responsible for the remarkable properties of the fabricated nanopillars in dry conditions and also under water.” says Zhao. The behavior of this dry adhesive makes it an ideal candidate for robotic and medical applications.