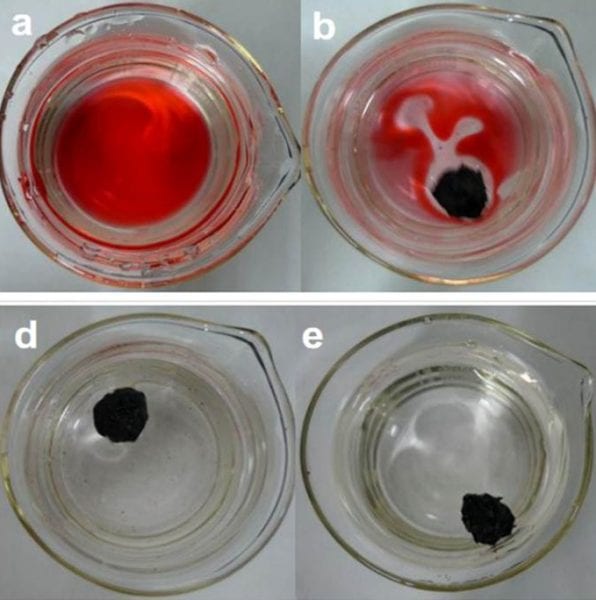

Absorption of dodecane marked with red dye from artificial seawater using the graphene sponge. The absorption process was complete in 80 seconds (click to enlarge image).

Since the discovery and isolation of graphene, physical scientists have been fascinated by the unique physics displayed by the truly two dimensional material, and materials scientists have been scrambling to harness these unique properties to develop its use in one or more “killer applications”. Graphene has been proposed for a multitude of high-tech applications, including transparent conductors, fillers for polymeric composites, and electronic heat sinks, to take advantage of its exceptional electrical, mechanical, and thermal properties (for example). However, according to recent results by Professor Rodney Ruoff and co-workers, another more crude application may beat them all to the marketplace: oil spill cleanup.

Many different types of materials have been proposed or tested for use in cleaning up oil spills, including zeolites, polymers, activated carbon, and even sawdust. Selective absorption capacity of the oil layer is of paramount importance in such an application, and the toxicity of the absorbent itself is also an important consideration.

In Ruoff’s work, a sponge-like graphene structure was fabricated by reducing graphene oxide and then applying a hydrothermal molding procedure in order to achieve a morphology with a high surface area. The researchers then tested the absorbance properties of this material for removing various commercial petroleum products (including kerosene, pump oil, fats, and organic solvents) from artificial seawater.

The remarkable results showed that the graphene sponge absorbed up to 86 times its weight, which was higher than all other common absorbents. The absorbed hydrocarbons were then subsequently recovered from the sponge with a 99% yield using simple heating. Using this procedure, the graphene sponge could then be regenerated and reused up to 10 times without a drop in performance. These exciting results could mean new hope in the unfortunate case of an environmental oil spill, but this type of technology could also be applied in more routine wastewater treatment applications or with industrial separations. The high-tech applications of graphene will come, but, with continued development in this direction, graphene’s first “killer application” may not be high-tech at all.